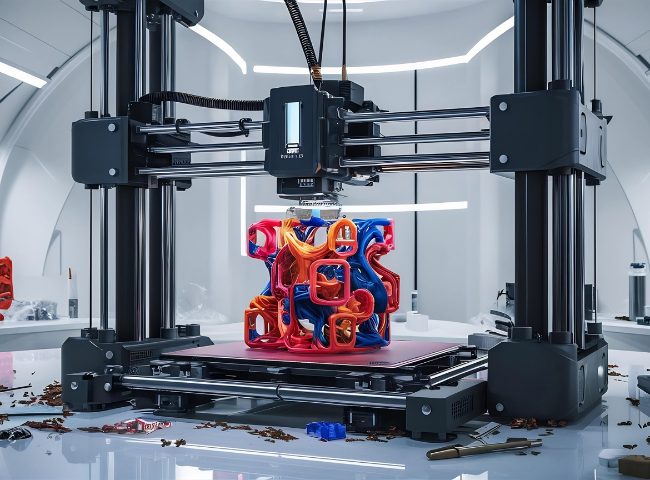

The global manufacturing landscape is undergoing a profound transformation, led by digital innovation and intelligent production methods. Among these, 3D printing which is also known as additive manufacturing, has emerged as a pivotal technology redefining how products are designed, developed, and delivered. Together with advanced manufacturing techniques, it is helping industries achieve unprecedented levels of precision, speed, and customization.

From conceptualization to final production, these technologies are reshaping the way engineers and manufacturers think about product creation. Instead of traditional subtractive processes that rely on material removal, additive manufacturing builds components layer by layer, using only the exact material needed. This shift not only minimizes waste but also opens new frontiers in design flexibility and performance optimization.

Accelerating Product Development through Rapid Prototyping

Time-to-market is one of the most critical factors in today’s competitive industries. 3D printing allows design teams to move from a digital model to a tangible prototype within hours rather than weeks. This rapid prototyping capability empowers engineers to test multiple design iterations, evaluate performance, and make real-time adjustments during the development phase.

Such speed enables faster validation of concepts and smoother collaboration between design, engineering, and manufacturing teams. It also reduces dependency on external tooling, allowing design cycles to become more agile and cost-effective. For sectors like automotive, aerospace, and healthcare, where innovation cycles are short, this flexibility is a significant advantage.

Enhancing Precision and Complexity in Design

Traditional manufacturing methods often limit designers due to tooling constraints and geometric restrictions. Additive manufacturing eliminates these barriers, allowing the creation of complex, lightweight, and organic shapes that were once considered impossible or uneconomical to produce.

Engineers can integrate multiple components into a single printed structure, reducing assembly steps and potential failure points. The result is a more efficient, durable, and precise product design. Advanced computational modeling and simulation tools further enhance this process, ensuring that designs are optimized for both functionality and manufacturability before production begins.

Material Innovation and Performance Optimization

The evolution of 3D printing has gone far beyond simple plastics. Modern additive manufacturing supports a wide range of materials from high-performance polymers and composites to metals such as titanium, aluminum, and stainless steel. Each material offers distinct mechanical and thermal properties, enabling manufacturers to select the right composition for specific applications.

This versatility promotes innovation in performance-critical industries such as aerospace, medical devices, and industrial machinery. For example, components can now be engineered for lightweight strength, corrosion resistance, or thermal efficiency depending on operational needs. The ability to produce custom parts with specialized properties adds tremendous value to end-user applications.

Sustainability and Resource Efficiency

Sustainability is no longer a peripheral goal but a core business imperative. Additive manufacturing naturally supports this shift due to its efficient use of materials and energy. Since components are built layer by layer, material waste is drastically reduced compared to conventional machining methods.

Furthermore, local on-demand production minimizes transportation and warehousing needs, contributing to a smaller carbon footprint. Lightweight designs achieved through topology optimization reduce fuel consumption in transportation and aviation sectors. The convergence of sustainability and advanced manufacturing is not only environmentally responsible but also strategically beneficial for long-term competitiveness.

Customization and Scalability in Production

Another defining advantage of 3D printing is the ability to offer mass customization. Manufacturers can produce unique or limited-edition products without the need for expensive tooling or setup changes. Whether it’s custom medical implants, tailored automotive interiors, or specialized industrial components, additive manufacturing provides the flexibility to meet individual specifications without compromising efficiency.

At the same time, advanced manufacturing systems have evolved to support scalable production. Hybrid approaches that combine additive and subtractive processes deliver both customization and repeatability. Automation, robotics, and intelligent material handling systems further enhance throughput and quality consistency, making it possible to meet large-scale industrial demands while maintaining the agility of digital production.

Quality Assurance through Simulation and Testing

Ensuring quality in additive manufacturing requires a deep understanding of process parameters and material behavior. Advanced simulation tools help predict how designs will perform under real-world conditions, allowing early identification of potential defects. Continuous monitoring of build parameters, coupled with post-processing analysis, ensures each component meets stringent performance and safety standards.

These predictive insights also reduce rework and material costs, ensuring that production remains both reliable and efficient. The integration of inspection technologies such as 3D scanning and non-destructive testing (NDT) provides added layers of precision in validation and verification.

As organizations continue to welcome digital transformation, the ability to adapt to real-time demands, reduce waste, and enhance customization will define success in the years ahead.

Vee Technologies’ adoption of 3D printing and advanced manufacturing principles is part of a broader vision to redefine product engineering. Through integrated design, precision modeling, and end-to-end digital manufacturing support, the company helps clients accelerate innovation while maintaining uncompromised quality and efficiency.