How Digital Twins Enable Sustainable Manufacturing

Sustainability is no longer optional for manufacturers. Organizations worldwide are seeking ways to reduce waste, minimize energy consumption, and extend product life cycles, while still accelerating time to market. One of the most transformative enablers in this shift is the Digital Twin.

While Vee Technologies does not market “digital twin services” as a standalone offering, the company actively integrates digital twin simulations, data driven engineering, and advanced digital manufacturing techniques across its Product Engineering and Manufacturing Engineering services. These capabilities directly support more sustainable, efficient, and intelligent manufacturing processes, aligning with global industry trends.

What is a Digital Twin in the Manufacturing Context?

A digital twin is a virtual, dynamically updated representation of a physical product or process. It allows engineers to simulate performance, test design changes, assess manufacturing behavior, and evaluate lifecycle impacts, before any physical resources are wasted.

Vee Technologies incorporates digital twin principles through:

- Simulation-driven design optimization

- Manufacturing simulation & analysis

- Data-rich modeling and engineering analytics

This ensures that product and manufacturing decisions are based on predictive insights rather than trial and error.

1. Digital Twins Reduce Material Waste Through Virtual Validation

One of the biggest sustainability advantages of digital twins is their ability to drastically reduce scrap and rework.

Vee Technologies leverages simulation and digital analysis tools to refine design and manufacturability before investing in tooling or production. Their engineering workflow integrates:

- CAD/CAM/CAE tools

- Finite Element Analysis (FEA)

- Digital twin simulations that test product behavior under various conditions

This data driven approach helps:

- Eliminate design flaws early

- Reduce prototype cycles

- Minimize defective or wasted components

- Lower the carbon footprint associated with physical testing

By catching issues virtually, manufacturers consume fewer materials and significantly reduce environmental impact.

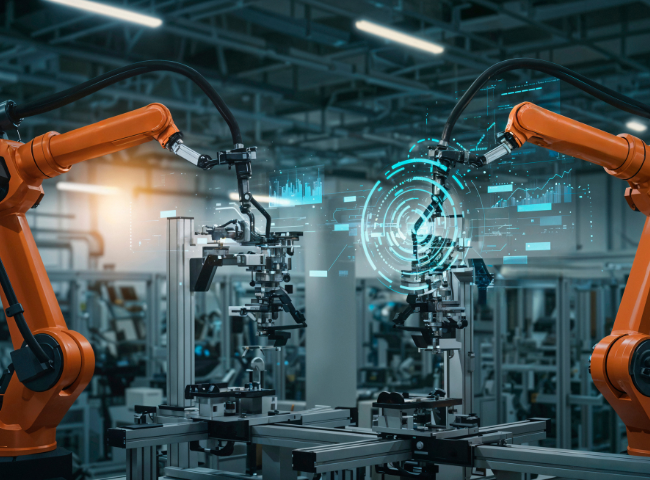

2. Enhancing Energy Efficiency Through Smart Factory Insights

Sustainable manufacturing requires insights into energy usage, production efficiency, and system performance. Vee Technologies supports this through digital manufacturing and smart factory solutions, which bridge digital simulations with real world production environments.

These capabilities enable manufacturers to:

- Monitor machine and process performance

- Identify energy inefficiencies

- Reduce unnecessary operations

- Optimize resource allocation

A digital twin’s real time and simulation-driven insights empower organizations to design production lines that operate with fewer emissions and lower energy demand.

3. Enabling Sustainable Product Life Cycles Through Data Rich Design

Vee Technologies’ Product Engineering Solutions use Data Rich Design to provide detailed engineering data that improves a product’s lifecycle sustainability. This includes supporting product decisions around materials, manufacturability, and performance.

Data driven design helps manufacturers:

- Increase product longevity

- Improve reliability

- Reduce maintenance needs

- Optimize component reuse across product generations

A virtual model not only predicts physical performance but also supports eco friendly design alternatives right from concept.

4. Supporting Sustainable Production with Manufacturing Engineering

Sustainability is strengthened when the transition from digital design to physical production is seamless. Vee Technologies’ Manufacturing Engineering Services include:

- Process planning & optimization

- Tooling development

- CNC programming & automation

- Digital manufacturing & smart factory solutions

These services integrate with digital twin simulations to create environmentally responsible production workflows that deliver:

- Lower cycle times

- Higher production yield

- Reduced machine idle time

- Minimized scrap and process inefficiencies

Manufacturers achieve sustainability goals while improving throughput and consistency.

5. Faster, Leaner Production Through Predictive Engineering

Predictive insights derived from digital twin simulations help manufacturers anticipate system failures, quality issues, or performance bottlenecks much earlier in the cycle.

Vee Technologies’ engineering teams combine simulation tools, analysis, and design optimization methods to ensure manufacturability and reliability before production begins. This reduces:

- Downtime

- Rework

- Resource-intensive maintenance

The result is a leaner, more sustainable production ecosystem.

Digital twins are redefining sustainable manufacturing by merging virtual intelligence with physical operational excellence. By embedding advanced digital insights into every stage of the engineering lifecycle, Vee Technologies empowers organizations to achieve measurable sustainability outcomes, without compromising performance or profitability.