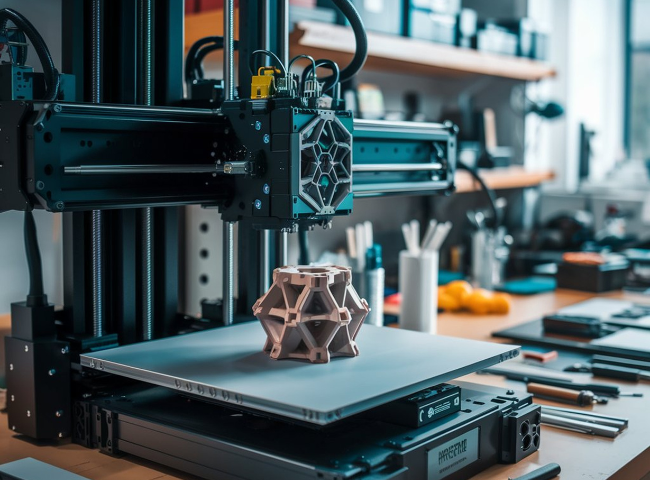

How 3D Printing is Transforming Modern Product Engineering

3D printing has rapidly evolved from a niche prototyping tool into a transformative force in modern product engineering. Organizations today demand faster innovation cycles, reduced manufacturing costs, and greater design flexibility, and 3D printing delivers precisely that.

Vee Technologies supports these goals through its comprehensive 3D Printing Services, enabling businesses to turn design concepts into functional, high precision parts with remarkable speed and efficiency.

Enabling Rapid Prototyping and Faster Product Development

One of the biggest advantages of 3D printing is its ability to accelerate prototyping. Instead of waiting weeks for traditional machining processes, businesses can now create functional and deliverable prototypes in significantly less time.

Vee Technologies uses 3D printing to support part design, product prototyping, and the production of essential tools or components, allowing companies to iterate faster and improve design accuracy early in the development cycle.

This rapid prototyping capability reduces engineering lead time and helps teams identify design improvements before costly investments in tooling or production.

Optimizing Product Performance Through Advanced Materials & Techniques

3D printing is not just fast, it is a pathway to better performance. With the ability to produce simplified assemblies, reduced weight components, and highly functional geometries, organizations can achieve design outcomes that are difficult or impossible with traditional manufacturing.

Vee Technologies enhances these benefits with post processing services, including:

- Support clearance

- Painting

- Chemical treatments

These steps ensure the final printed parts meet the required aesthetic, functional, and durability standards.

World Class Print Technologies for Diverse Engineering Needs

To serve a wide range of product engineering requirements, Vee Technologies uses multiple advanced 3D printing technologies, including:

- PolyJet (PJ)

- Multi Jet Printing (MJP)

- Micro SLA

- Fused Filament Fabrication (FFF)

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- Film Transferring Image (FTI)

These technologies enable exceptional flexibility in material selection, surface finish, accuracy, and mechanical strength, which are the key factors that influence usability during testing and production.

Supporting Multiple Industry Sectors

3D printing at Vee Technologies is not limited to a single sector. Their services support industries such as:

- Engineering

- Electronics

- Aerospace

- Architecture

- Product Design

This cross industry expertise allows the Product Engineering division to tailor 3D printing solutions for unique functional requirements, whether it’s lightweight aerospace parts, architectural models, or compact electronic enclosures.

Strengthened by Technical Education & Research Infrastructure

A standout advantage for Vee Technologies is the strength of its technical educational institutions, which house well equipped labs capable of delivering world class 3D prints. These labs support innovation, experimentation, and advanced prototyping, ensuring high quality outputs that meet global product engineering standards.

This ecosystem of research, education, and engineering expertise ensures clients benefit from cutting edge knowledge and consistently reliable prototyping capabilities.

Cost Effective, On Time, High Quality Output

The value of 3D printing lies not just in speed and flexibility but also in cost efficiency. By avoiding complex machining, molds, and extensive tooling, organizations can reduce manufacturing costs, especially in early design stages.

Vee Technologies prioritizes:

- Timely communication

- High quality 3D printers

- Competitive pricing

- On time delivery

It ensures that even complex or unique prototyping requirements are handled efficiently and within budget.

Transforming Product Engineering from Concept to Production

3D printing is more than a development tool, it's a catalyst for innovation across the entire product lifecycle. From initial concept sketches to design verification and pre production testing, 3D printing helps organizations refine products faster and more accurately.

With Vee Technologies’ integrated Product Engineering Solutions, companies gain access to:

- Rapid concept validation

- Functional prototypes

- Lightweight, optimized designs

- Small batch production support

- Seamless transition into manufacturing engineering

This bridge from prototype to production accelerates time to market and enhances product performance.

3D printing is reshaping the future of modern product engineering, making innovation faster, smarter, and more accessible. With its advanced print technologies, experienced engineering teams, and strong R\&D ecosystem, Vee Technologies enables businesses to fully leverage the power of additive manufacturing.